Aluminum Wheel Cornering Fatigue Testing

Steel Wheel Cornering Fatigue Testing

What is Cornering Fatigue Testing for Aluminum and Steel Wheels?

Cornering fatigue testing for Aluminum Wheels and Steel Wheels is designed to test wheel sizes from 12" to 24" in diameter to specific SAE standards for passenger cars, light trucks, recreational and utility trailers. Cornering testing simulates a vehicle on an oval track performing cornering maneuvers for an extended period of time.

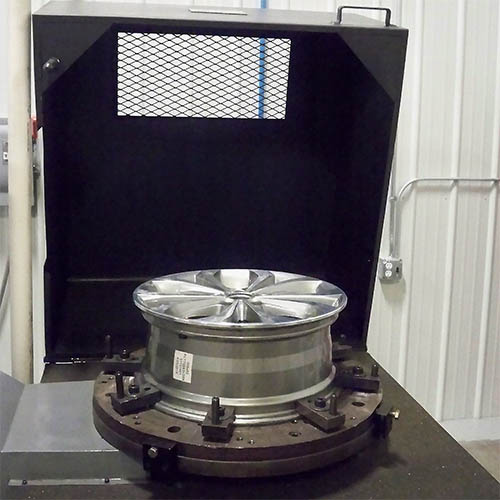

Wheel Cornering Fatigue Testing Process

Cornering testing for aluminum wheels and steel wheels are very similar. The wheel is mounted flat and centered on the cornering test machines. Loads are calculated by using the relevant SAE standard. The wheel simulates cornering maneuvers for a specific duration. When the cycle is complete the wheel undergoes a Liquid Penetrant Test (LPT) to detect possible failures.

Why Choose AQTS?

Proper Cornering Fatigue testing performed by AQTS helps ensure safe performance of a wheel throughout the entire product life cycle. Our highly trained technicians leave no detail overlooked so you can have confidence in every turn.